Introduction:

Standard AC motors can adjust their speed and torque their speed and torque adjusted using AC LV drive thanks to built-in features. AC drives replace the usage of DC and slip-ring motors with their management systems and with their management systems in addition to induction motors.

Low voltage AC drives or AC LV drive from ABB increase productivity, save energy use and optimize processes. The product line caters to our clients’ whole range of requirements of our clients, from micro drives used in machine construction to industrial drives used to manage production lines. ABB drives can be properly manufactured to accommodate more sophisticated client needs or purchased right away from stock.

Benefits of LV Drives:

Low voltage technology dominates the AC drive industry for both high- and low-power applications, notwithstanding the advantages of adopting moderate voltage AC drives for large horsepower motors. This is due to several factors, not the least of which are price and accessibility. In the past, voltage levels drives have been carefully made to order, with limited volume manufacture, greater cost, and generally lengthy lead times.

Even though more conventional medium voltage (MV) drive options are now being mainly offered by manufacturers, and improvements in high-voltage semiconductor technology have reduced the cost of electronics, MV drives are still significantly more expensive (at least initially) and less widely accessible than Low-voltage or LV drives.

For the same power output, medium-voltage drives use less current than low-voltage drives. In addition to saving energy, the decreased current draw makes it possible to employ smaller, less expensive wires. However, a large variety of manufacturers provide low-voltage or LV drives as standard items, but medium-voltage drives remain primarily custom-engineered devices.

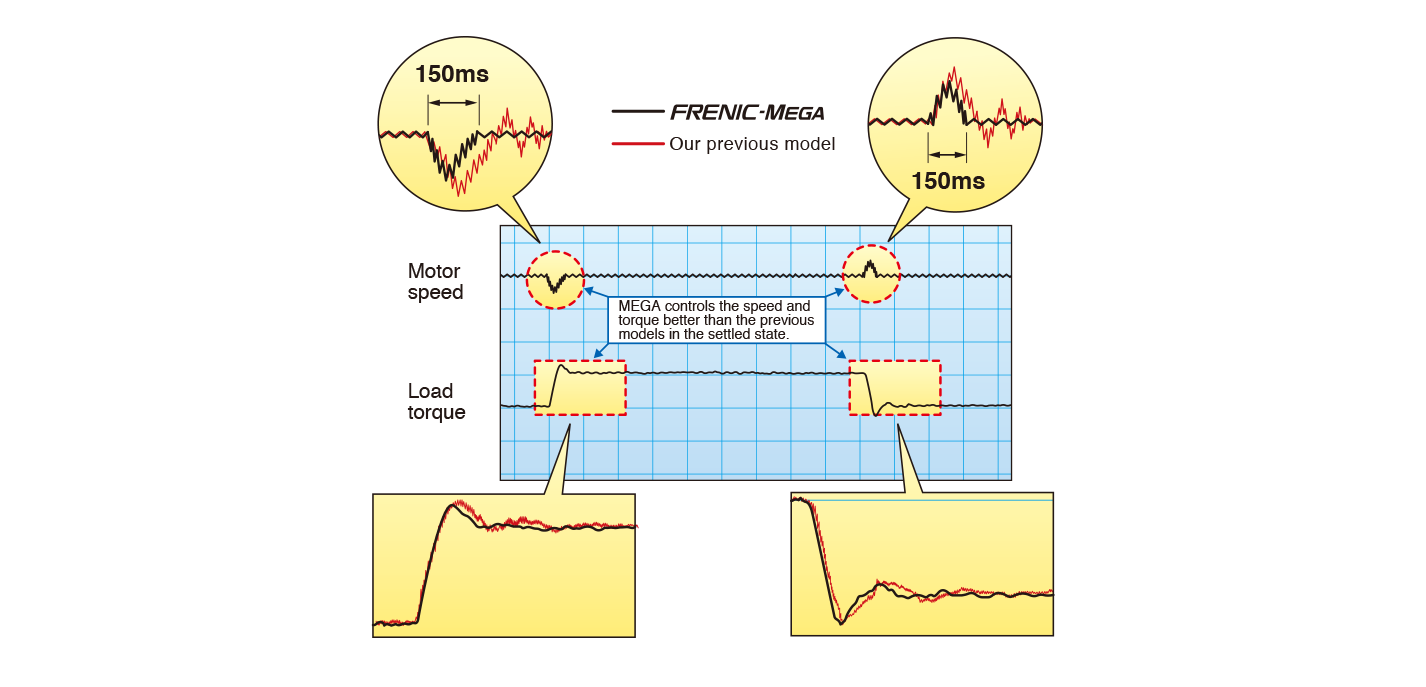

Frenic mega Fuji Electric

Fuji Electric has raised the bar for inverter performance with the Frenic mega Fuji electric variable drive.

Offering expanded power ratings and flexible configurations that support 1/2 HP up to 1,000 HP AC drive/variable frequency drive (VFD) / v/ Hz vector drive applications – these inverters are designed for long lifecycles and improved maintenance functions.

Frenic Aqua Fuji Electric

The Frenic Aqua Fuji Electric series is a dedicated inverter that helps to control pumps and motors. It helps energy-saving of pumps by eliminating ineffectual operations by regulating the amount of water

Use of LV drive:

Low voltage (LV) drives are available as either a current source inverter (CSI) or a voltage source inverter (VSI), however, VSI variants with pulse-width modulation are more prevalent. In the inverter sector of voltage source inverter, pulse-width modulation (VSI-PWM) drives, and insulated-gate bipolar transistor (IGBT) switching components are frequently used.

IGBTs have a high switching frequency, lowering motor heating and decreasing a high switching frequency, which lowers motor heating and decreases harmonics. However, this increased switching frequency has a disadvantage because it causes a greater voltage rise (DV/DT) rate than it causes a greater rate voltage rise (DV/DT), which can result in reflected waves that harm the motor insulation and cables. The reflected waves can be properly reduced by output reactors or filters, but these increase the drive system’s cost.

LV drives are frequently used with medium voltage motors, particularly those rated at 2300 or 4160 V, even though they run at a lower voltage. A step-up transformer must be carefully added to the LV drive to use it with a medium-voltage motor. To match the motor voltage, the transformer raises the inverter’s output voltage. For applications requiring only a single-phase supply, LV drives may run on single-phase power input and provide three-phase voltage to the motor.

Conclusion:

The low voltage PWM drive may be properly adjusted to employ flux vector control in situations when high beginning torque is mainly required (usually above 150 percent). This technique, also known as field-oriented control, offers independent management of the magnetizing and torque-producing elements of the stator current, leading to more reliable torque generation.

Both high- and low-power applications can benefit from low-voltage drivers. Low voltage drives are frequently used due to their comparatively lower cost, smaller size, and more availability, although medium voltage drives offer the advantage of reduced current draw and lower energy usage. Frenic Aqua Fuji Electric, Frenic Mega Fuji electric, etc offer great LV drives at lower costs.