SCADA, or supervisory control and data acquisition, is a control system architecture that includes computers, networked data transfers, and graphical interfaces for high-level monitoring of equipment and processes. It also includes sensors and other devices that connect with process equipment or machinery, such as programmable controllers. It is best given by the SCADA Software distributor.

The SCADA computer system handles the operator interfaces that enable surveillance and the giving of process commands, such as controller set point modifications. Subordinated processes, such as actual control logic or controller computations, carry out by networked modules that link to field sensors and actuators.

The SCADA idea establishes to provide a common way of remote access to a range of local control modules from various manufacturers, with access via standard automation protocols. Connect with the best SCADA Software distributor for better software.

In practice, big SCADA systems have evolved to work with distributed control systems, while utilising many modes of interacting with the plant.

They can regulate large-scale activities involving several sites and work over vast and small distances. Despite worries that SCADA systems are vulnerable to cyber warfare assaults, it is one of the most utilised forms of industrial control systems.

Usage of SCADA Software

The SCADA principle uses to build both big and small systems. Depending on the application, these systems might include hundreds to thousands of current control. As examples, consider the following industrial, infrastructural, and facility-based processes:

Manufacturing, power generation, process control, fabrication, and refining are examples of industrial processes that can operate in continuous, repetitive, batch, or discrete modes.

Water treatment and distribution, gas pipelines, wastewater collection and treatment, electric power distribution and transmission and wind farms are examples of infrastructure activities that can be public or private.

Building, airport, ship, and space station procedures are examples of facility processes. They check and regulate HVAC systems (heating, ventilation, and air conditioning), as well as access and energy use.

SCADA systems, but, might well have security vulnerabilities, thus they should analyse to identify risks and remedies applied to minimise such risks. Get the best software from SCADA Software Distributor.

System Components of SCADA

A SCADA system includes the following components:

Remote terminal units

RTUs, or remote terminal units, link to actuators and sensors in the process and connect to the supervisor’s computer system. RTUs feature integrated control capabilities and adhere to the IEC 61131-3 programming standard, as well as support mechanization via ladder logic, a functional block diagram, or several other languages.

Remote locations have little or no local infrastructure, so it is not uncommon to find RTUs powered by a small solar system, communicating via radio, GSM, or satellite, and rugged to withstand temperatures ranging from -20C to +70C or even -40C to +85C without the help of external heating or cooling equipment.

Supervisory computers

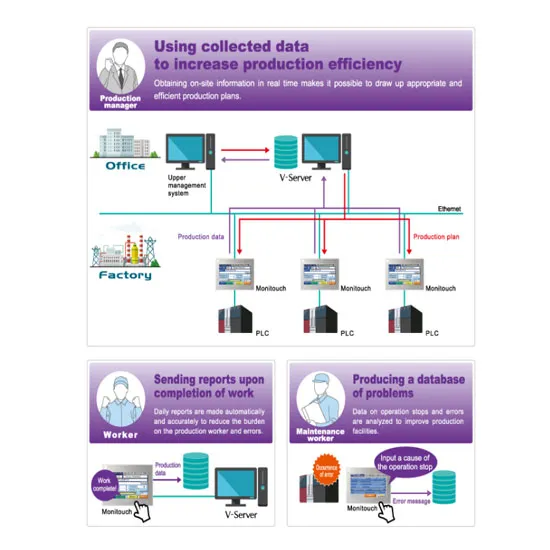

This serves as the heart of the SCADA system, collecting process data and transmitting control directives to field-connected equipment. It refers to the software that communicates with the field link controllers (RTUs and PLCs), as well as the HMI software that runs on operator workstations.

In smaller SCADA systems, the monitoring computer may be a single PC, in which instance the HMI integrate. The master station in larger SCADA systems may have various HMIs housed on client PCs, distributed software applications, many servers for data acquisition, and disaster recovery locations.

Infrastructure for Communication

This interfaces the supervisory computer system with the RTUs and PLCs, and it may use standard industry or manufacturer-specific protocols. Both RTUs and PLCs function on the process control in near-real time, using the most recent command from the central controller.

The breakdown of the network infrastructure does not prevent the plant controls, and if communications restore, the operator can resume monitoring and control. Some important systems will have twin redundant data highways, which will cable across many pathways.

PLCs

These, sometimes known as PLCs, links to sensors and devices in the process and link to the central controller. PLCs in industrial automation are often connected to the SCADA system at fast speeds. In distant applications, such as a major water treatment plant, PLCs can connect to SCADA through a wireless link, or they can use an RTU to handle communications. PLCs were the first substrate for the IEC 61131-3 programming languages and were particularly built for control. PLCs utilise distant sites with a high I/O count, rather than an RTU alone, for cost reasons.

SCADA Software Distributor

There is various Scada Service provider in India with high-quality software. SCADA Software can get from distributors like “Fscgroup” who count as the best SCADA Software Distributor in India. There are other distributors like SCADA Software distributor in Delhi